General Information:

Conduct all operations SLOWLY. Safe operation requires moving panels into place one at a time.

Avoid stopping while moving the panels through intersections. The carriers may stop in an intersection and

appear stuck. If this happens, push panel back in the direction from which it came and try again.

For the best acoustical seal and proper alignment, it is important to maintain constant pressure against the

edge of the panel while setting seals.

If you notice that a partition is not hanging plumb, stop and go back and reset the panel. If you fail to do this,

panels will not make full contact and provide a poor acoustic seal.

Setting Up A Partition-

1. A typical partition consists of basic panel(s), an optional pass door, additional basic panels, and, last a

closure panel.

Stand in the center of the panel face. Using both hands, grasp it by the edges as high as possible and

gently pull it toward you. (Fig. 1) Carefully maneuver the panel out of the storage area. (Fig. 2 & 3) Move

the panel down the track to the required position. Once in place, push it firmly against the adjacent wall or

panel to insure a tight joint. You may place your foot against the bottom of the panel to hold it in place

while you extend the acoustical seals.

2. Seal Operation for Retractable Seals: Once the panel is in position, insert

the operating key over the exposed shaft in the panel's vertical edge (Fig. 4,

A).  While keeping the panel plumb, turn the operating key clockwise approximately

While keeping the panel plumb, turn the operating key clockwise approximately

190 degrees. This will extend the seals. Remove the operating

handle and repeat with remaining basic panels.

Setting the Final Closure Seals.

Final closure will be by either Lever Closure panel (with expanding

jamb) or Pivot Closure Panel which is permanently installed in the

opening.

a. Lever Closure Panel

Move the last panel into place. If you have retractable

seals, you will need to extend two seals on the last panel

in the opening. The first seal is located in the trail edge

of the panel (Fig. 6). Insert the operating key over the

exposed shaft in the vertical edge and turn key 190 degrees

clockwise to set the seal(s). (The shaft may be hidden from

view by the expanding post). To extend the second seal,

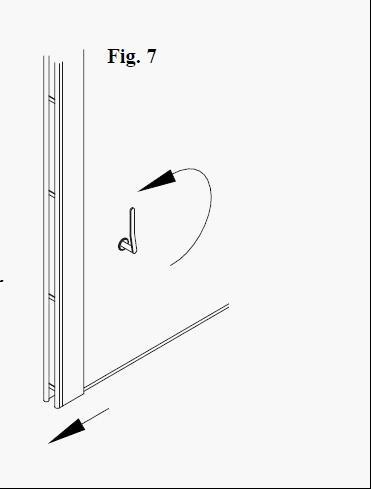

insert the operating key over the shaft located on the face of

the panel (Fig. 7). Turn the key clockwise until you feel

resistance against the wall. This action extends the closure

and completes the acoustical seal. Note: Make certain you

apply sufficient pressure to compress the vinyl seal against

the wall.

If the modular width is less than 33" the top seal on the Lever

Closure Panel is set separately from the bottom seal on all

models with top retractable seals. The operating mechanism

is located approximately 18" higher than the lower

mechanism.

Fig. 6

Fig. 7

Stacking/Storing The Partitions

1. If the partition has a pass door, open the door and retract the seals by reversing the

previous setup instructions. Close the door and make certain that it is latched.

2. Retract the Lever Closure Expanding Panel by inserting the operating key over the

shaft in the face of the panel and turn counter-clockwise to retract the closure.

Retract top and/or bottom seals on this panel by placing the key over the shaft in the

trail edge and rotate counter-clockwise.

3. Panels with Retractable Seals: Insert operating key onto the shaft of each panel

and fully rotate key counter-clockwise, retracting the top and bottom seal. Before

moving the panel, make certain that the seals have retracted. DO NOT MOVE

PANELS IF THE SEALS ARE NOT RETRACTED - PERMANENT DAMAGE COULD

RESULT. Separate panels and move to storage area. Repeat until all panels are

stacked.

VINYL FABRIC SURFACE AND EXPOSED TRIM AND SEALS

The vinyl surface of your Hufcor partition may be cleaned with warm water and mild soap.

Sponge the surface clean and wipe dry with a soft cloth. A soft brush may be used if dirt is

difficult to remove. Carbon tetrachloride may be used for removal of grease and oil.

CAUTION: Do not use lacquer thinner or other strong chemicals except those listed above.

Many floor cleaning materials contain chemicals harmful to vinyl. Care should be taken when

using such compounds near the partition.

CARPET/FABRIC SURFACE: Commercial carpet cleaners may be used to clean carpeted

surfaces. Follow the manufacturer's listed instructions.

MARKER BOARDS: Clean regularly with mild soap and water. To prevent soap buildup,

rinse well with clean water.

Regular care will keep your partitions in good working condition and prevent emergency service calls

or costly repairs. An annual inspection includes:

1. Clean and lightly lubricate all track running surfaces.

2. Check trolleys for any signs of abnormal wear or breakage.

3. Check out-of-plumb panels (indicating loose trolley bolts).

4. Check any exposed bolts in panel vertical edges.

5. Check track alignment at all joints and intersections.

6. Check lever closure (or pivot closure) and adjust as needed.

7. Check and make sure all top and bottom seals are functioning properly.

8. Operate pass door and adjust as needed.

9. Check for torn or malfunctioning sound seals.